Revolutionising design for manufacture and fast assembly in the aerospace industry:

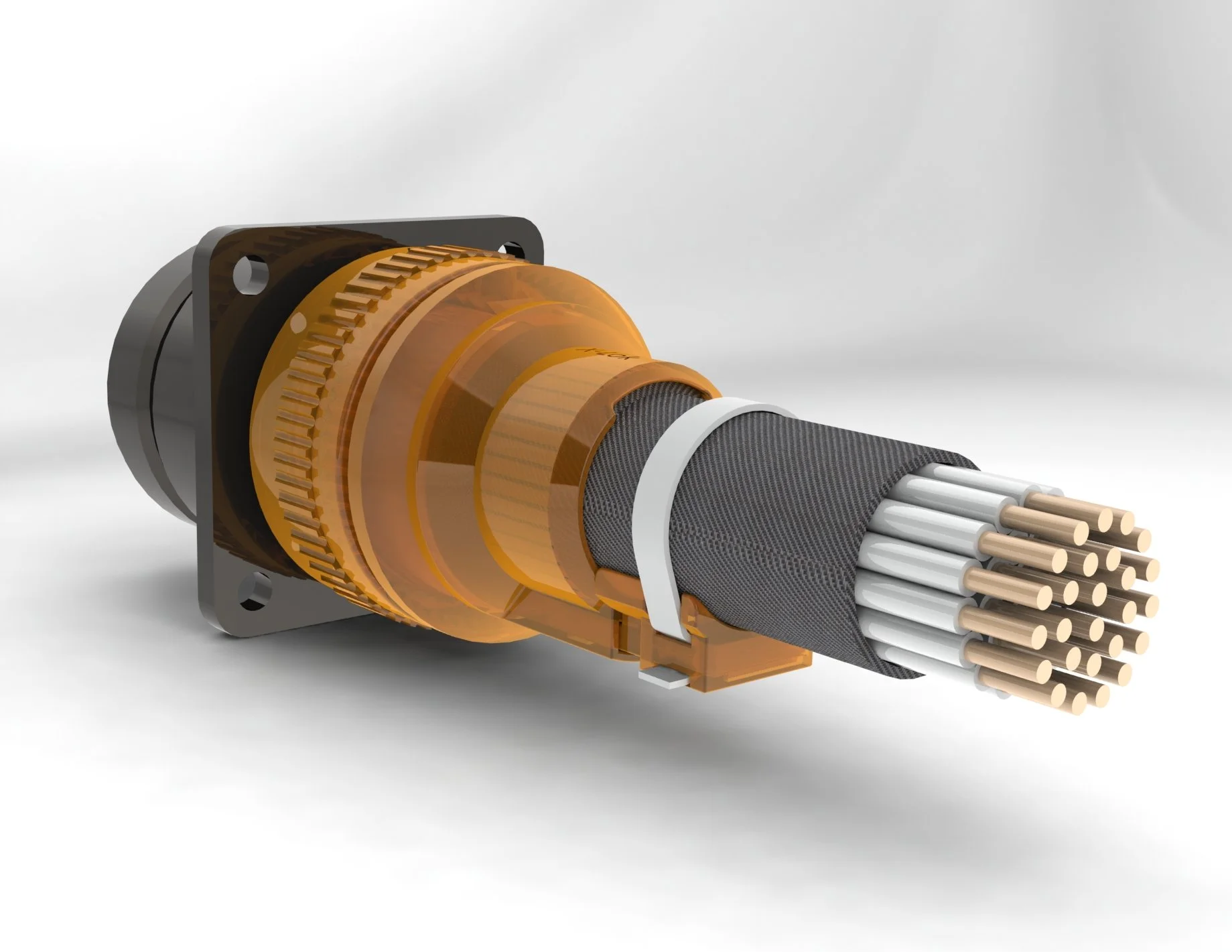

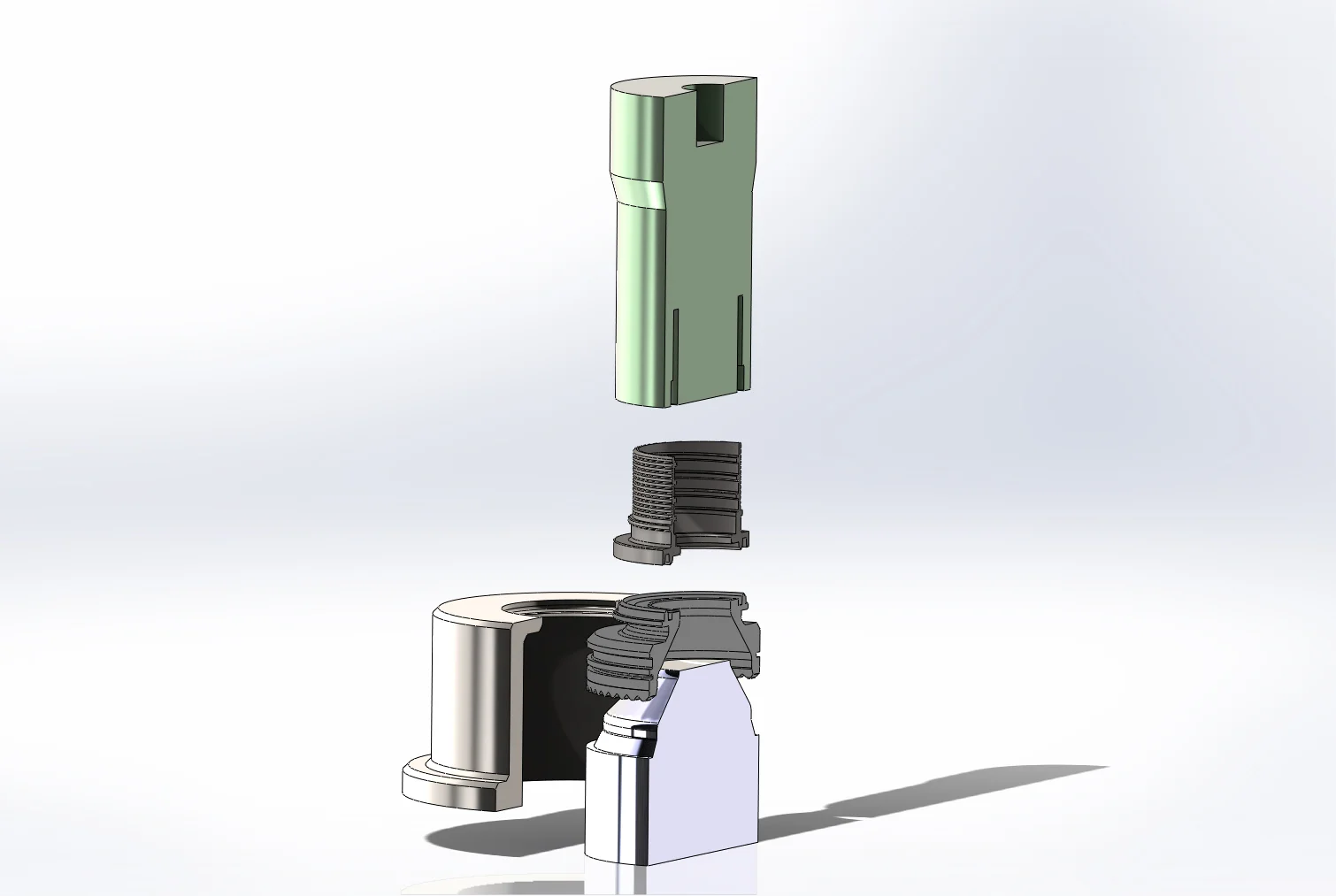

Unique tool-less system designed specifically for Open Wrappable Sleeve Technology

System designed for X-Lok Ltd

Tool-less backshell designed specifically for open sleeves eliminating all the costly build components: 66% lighter, 53% less expensive, 15% faster to build and install than conventional systems

Unique XC Micro self-locking lacing tape clips, showing threading loops (3) and locked (bottom right)

ABS1357 performance upgrade for Airbus A380 & A350XWB

System designed for Zodiac Interconnect

Deliverables for ABS1357 Project

Assembly time simplified and improved by a factor of 50 : 15 seconds vs 12 minutes

Introduced ultrasonic welding techniques, reducing metallisation costs by circa 40%

Introduced parallel collapsing core technology to facilitate direct injection & eliminate sprue waste

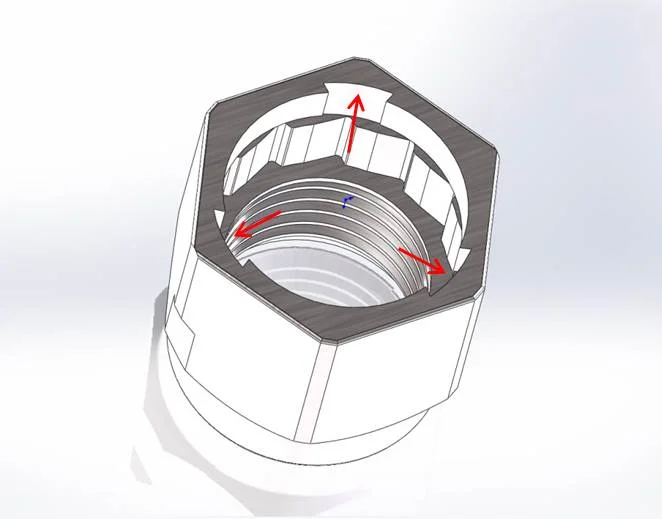

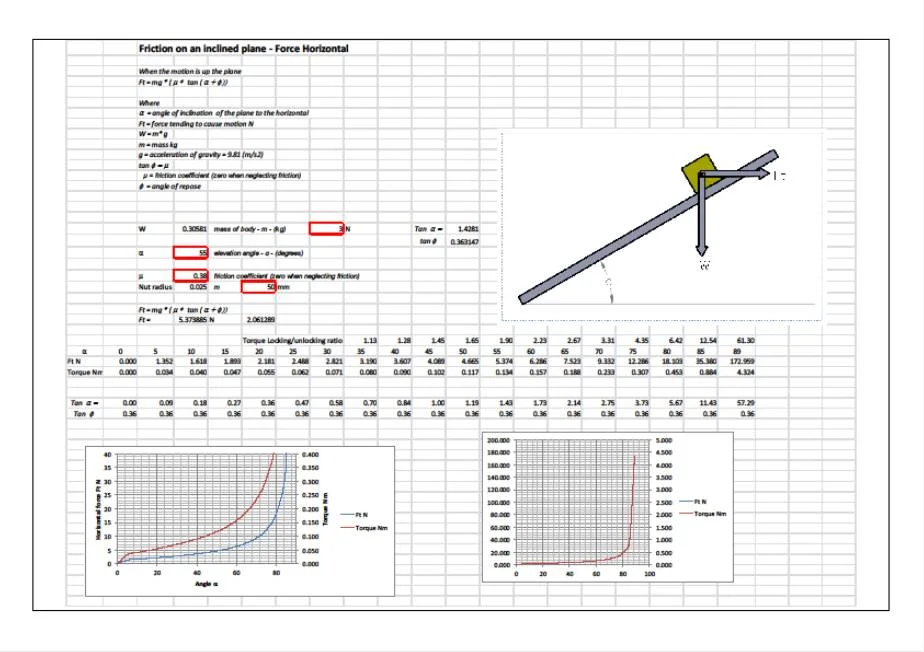

Incorporated a ratchet system to provide > 2 x the unmating force for anti-vibration performance

Change to composite material validated by FEA, reducing costs by 67% and weight by up to 47%

Research into the effects of metallisation and heat treatment on composites performance at 180°C

New plating specification providing 15kA lightning strike protection, higher corrosion resistance and increase in component strength by a factor of 1.4

Full scale matrix analysis of component dimensions, weights and assemblies, cross checked with Airbus standards and weight budgets

Negotiated anomalies with Airbus Toulouse with a view to harmonisation of standards

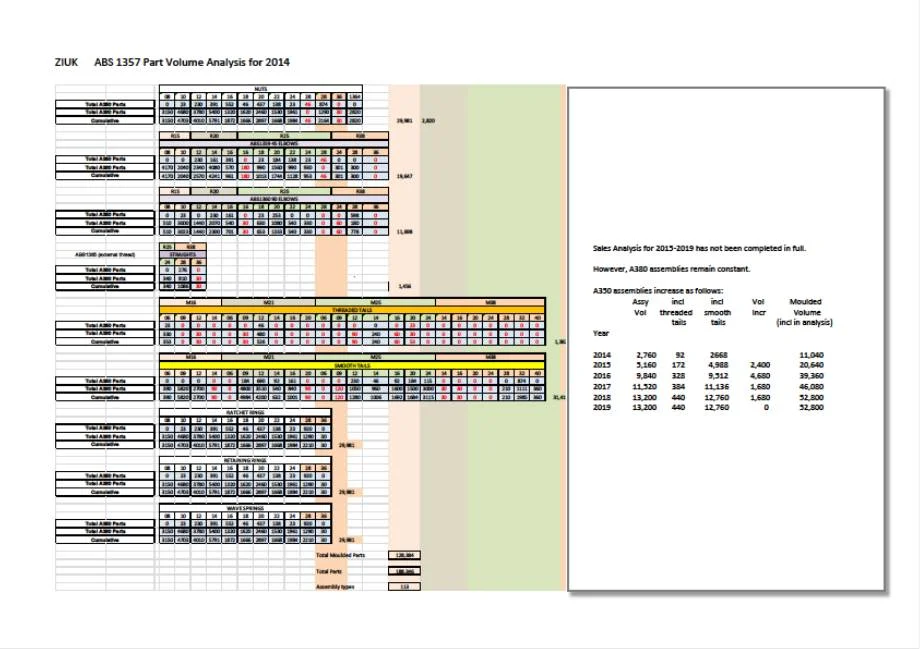

Sales analysis that reduced the £1.4m tooling budget by circa £250K

New marketing materials - colour coded visual aid to simplify the complexity of the full product range

Integration with the programme management and project planning teams

Negotiation of the CDR with Airbus Toulouse

FEA to prove performance at 180C

Introduction of Parallel Collapsing Cores - Saving Waste

DT Cores feed centrally with diaphragm or spider gate options dramatically reducing waste

Conventional gating can produce a substantial amount of sprue waste

Parallel collapsing cores create undercuts and threads in one fast action, eliminating unscrewing cores and long bolsters, reducing tooling costs

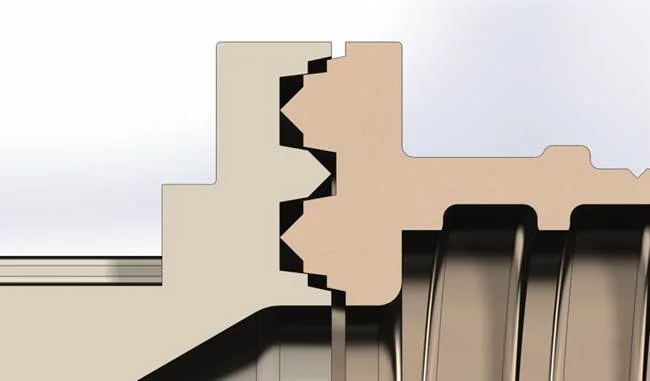

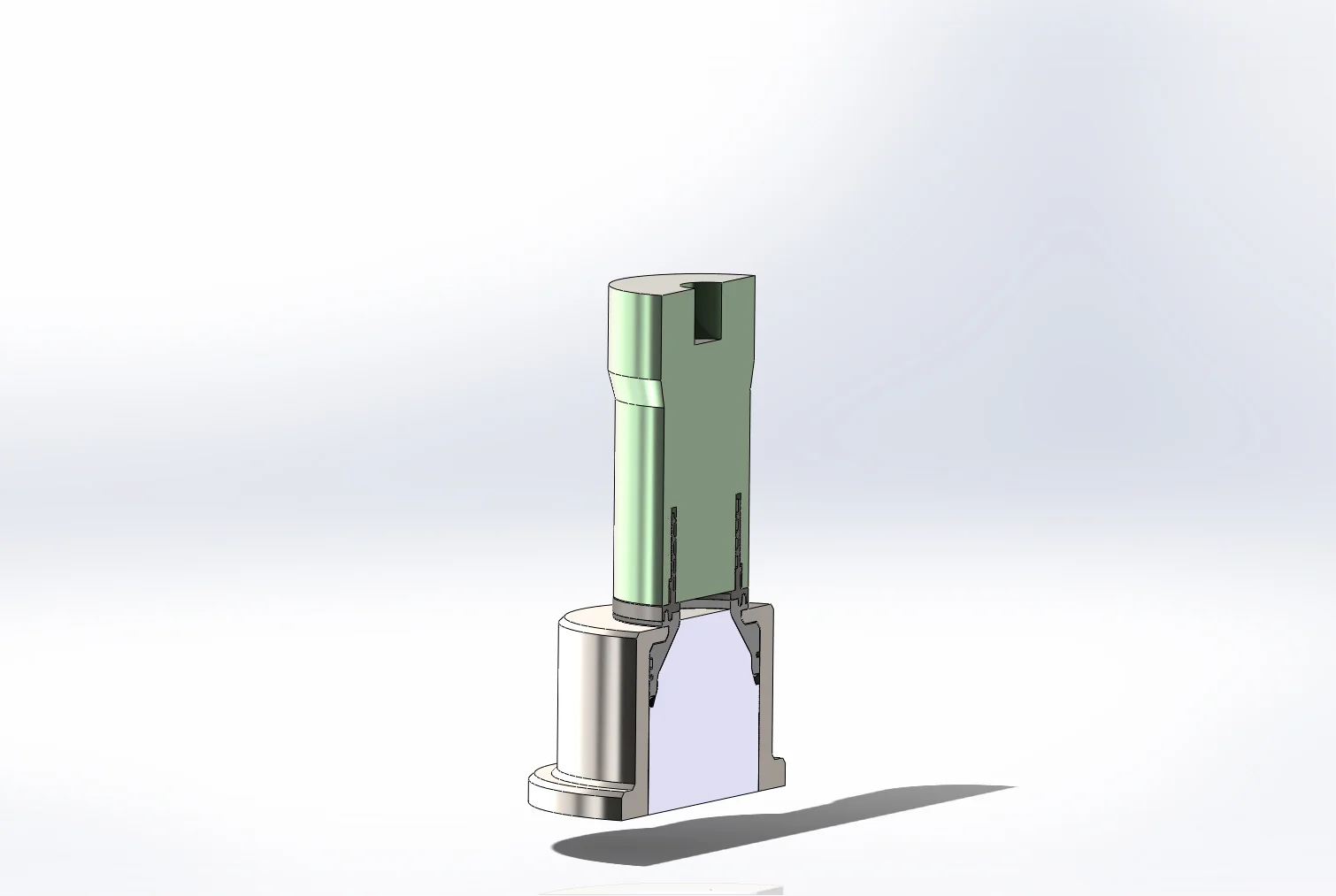

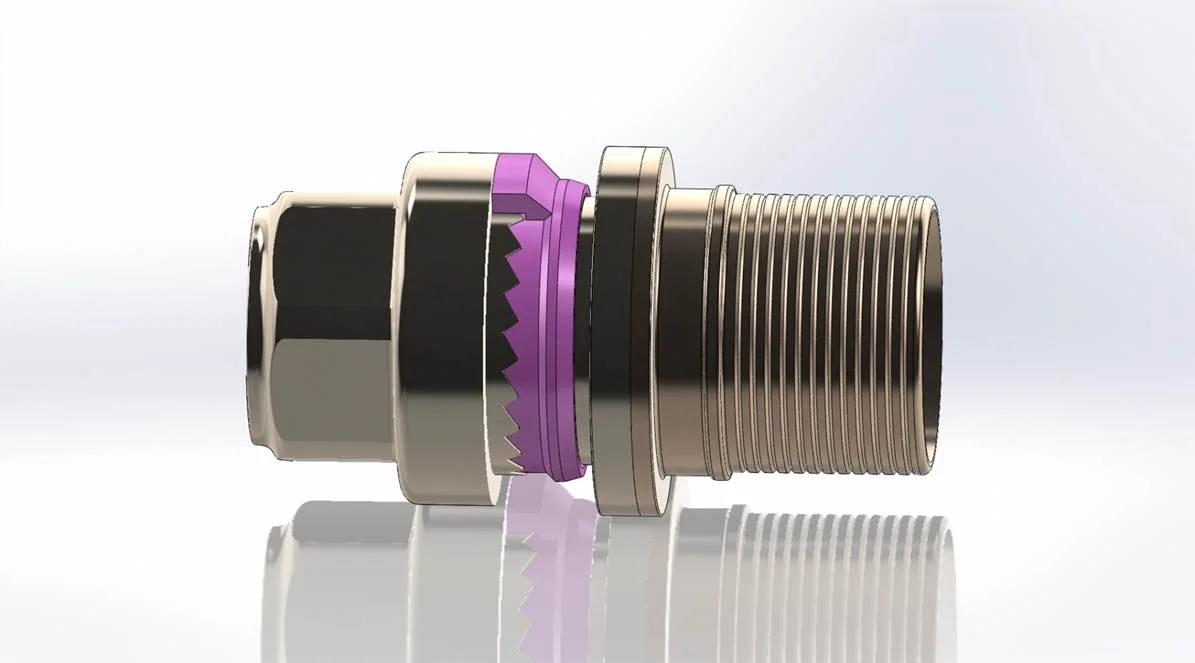

Comparative FEA Performance Studies

Old Design: 196MPa

No external supporting collar, local high stress points

Poorly positioned gates

Standard core creates breaks in annular support for the retaining ring

Unscrewing core employed for thread

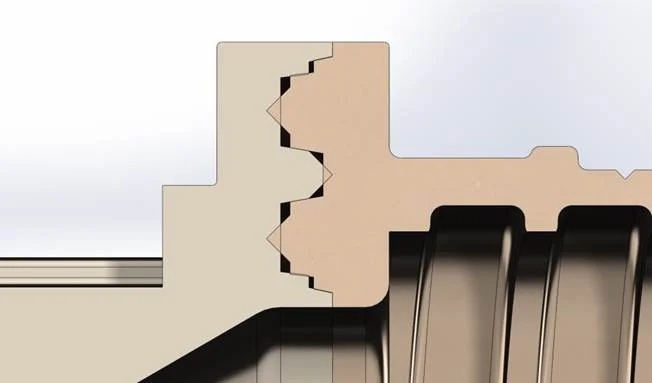

New Design: 79MPa

Supporting collar guarantees performance

Parallel collapsing core forms thread, undercut and ratchet

Central direct injection improves circularity

Ultrasonic welding design

Profiles balanced and symmetrical

Precise shut off design completely contains weld flash

Tight mating faces ensure perfect metallisation: single component saves 40% on metallisation costs

Heat treatment after metallisation achieves 15kA lightening strike and increases strength by a factor of 1.4

Exceptionally strong joint passes 2350N pull test

Engagement before welding: Gradual shut off contains flash

Weld partially consumes energy directors and interference shut-offs eliminate flash

Ultrasonic welding mandrel and vibratrode tool design

Parts are placed on the mandrel and locked in with a sleeve. The vibratrode imparts a circa 0.8 second charge at a precise frequency to weld the components together. Welds on even the smallest components withstood a 235 tonne pull test.

Design for improved metallisation performance and anti-vibration unlocking protection at 200°C

The ratchet ring supported by a wave spring is displaced as the nut is tightened. The unsymmetrical ratchet profile resists unlocking.

Rachet angle analysis and calculations

Sales Analysis for Tooling and Commercial teams

In depth analysis of sales, highlighting non-movers and establishing smooth bore tail preference to threaded bores, saving £250,000 on a £1.4 m tooling budget.